Two chamber ice chest experiment

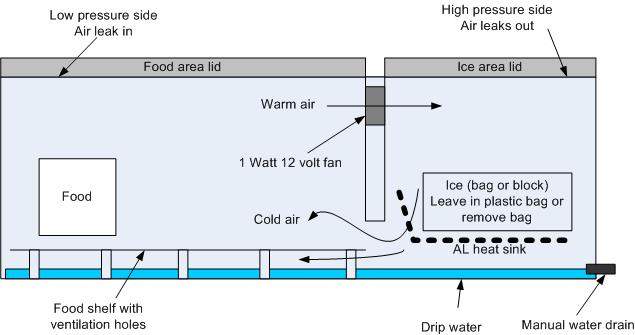

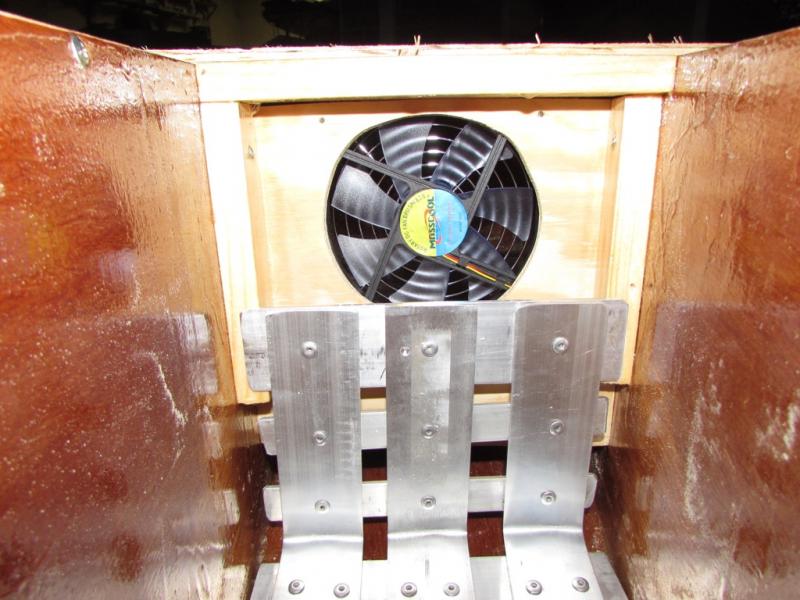

The idea here is to have a two chamber ice chest where one chamber holds ice and the second chamber holds food. There will be a natural air circulation set up between two chambers at different temperatures where cold air flows to the warm chamber at the bottom and warm air flows to the cold chamber at the top. A 1 watt fan is used to complement this air circulation, i.e. the fan blows air the same direction that it naturally would circulate in the chamber.

The ice sits on an aluminum heat sink and the ice melt just goes to the common bottom of both chambers. A platform in the food chamber keeps the food above the ice melt.

Also, there is a water drain. The majority of the ability of ice to cool is in the phase of ice simply going from solid to liquid. Once liquid water, most of the "work" has been expended so you lose a little by draining the ice melt out each day but its not significant (and worth it to not have the water at the bottom of the chest).

As an example, it takes 80 calories for 1 gram of ice to melt. It then only takes 8 calories for that same gram to go from 32F to 47F (about the warmest you want on an ice chest). So by draining the ice melt, you only lose about 10% of cooling effect of a bag of ice.

The idea for the two chamber chest is shown in the figure below.

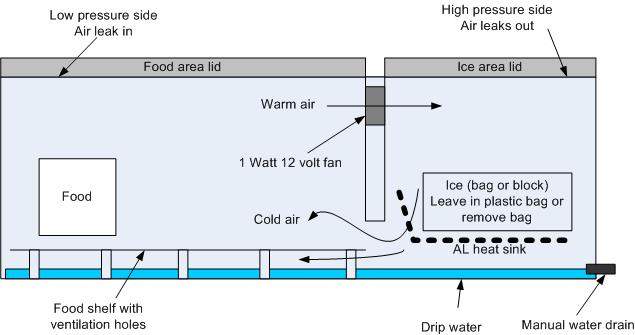

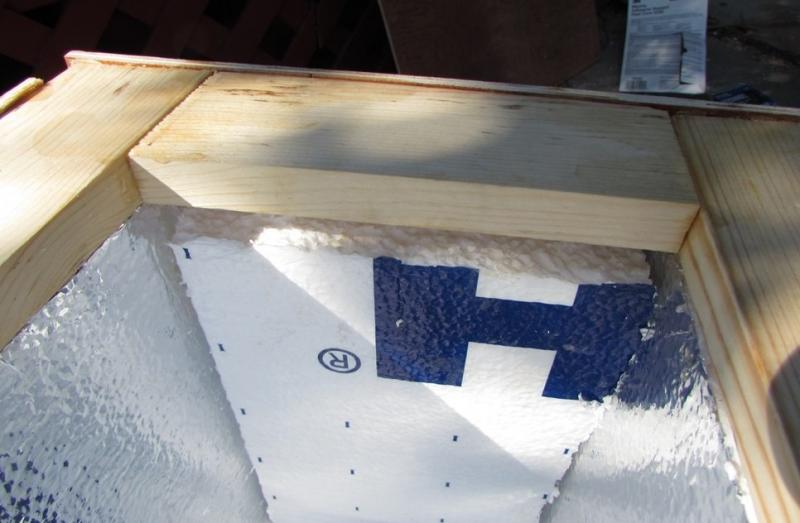

The two chamber chest ended up with 3 inches of foam insulation on the bottom and two inches of insulting foam on all the walls and the top covers.

There are two independent lids, one above each chamber.

Results.. we use two to three bags of ice per week depending on how much warm stuff is added to the ice chest. This is with draining the ice melt daily..

Figure below: fitting the foam for the final location (boat is a 1990 Macgregor 26S - old style under 10 hp with water ballast). The height was set up so that a gallon of milk or a glass bottle beer could sit upright with the food shelf in place.

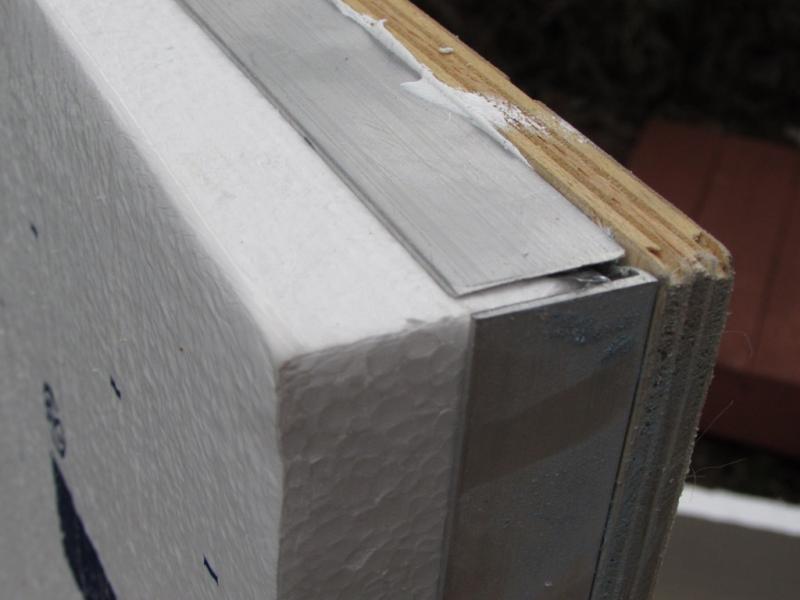

Picture below: two inch thick foam is used on the sides and the top cover. The bottom uses two inch thick foam plus one inch thick foam for three inches total.

Picture below: The inside was all fiberglass taped at the seams and all surfaces coated with epoxy to make it water proof.

Picture below. Current draw of the fan is 58 ma. This will accumulate 1.4 amp hours if left on 24 hours per day (a huge 25 to 35 times less power than an electric fridge). It turned out that the fan was normally not really needed as the natural air flow cooling was for the most part adequate. Using the fan did cool things faster when something warm was added to the chest and also kept the food area cooler. But using the fan also used up the ice faster.

Picture below. Stand off shelf in the food area keeps the food out of the ice melt. The white standoff is PVC plastic glued to the poly plastic sheet.

Picture below. The ice chamber takes crushed or block ice or cold bags. The second chamber can also be used as a regular ice chest.

Picture below. A comforter with a little sewing covers the top of the chest for a little extra insulation.