Propane heater ceiling "heat shield" plus Black Body radiator (rev 2.0 1/19/2022)

I purchased an outdoor Propane heater for an open patio with a relatively low roof and after buying the heater, discovered that the specification requires thirty inch clearance to the ceiling. I did not have this much ceiling height. Specs like this of course need to be taken seriously because of home owners insurance liability. What I did here is an experiment and does NOT follow this specification so use any ideas at your own risk! This page just describes this experiment and measured results to both keep the ceiling above the Propane heater cool and also capture and re-radiate the upwards wasted heat making the Propane heater more efficient..

Technical stuff. In this application, we care about radiated heat (infrared radiation) that is emitted from a hot object and convection heat that is carried by air current. A key parameter for radiated heat is Emissivity which varies between 1 and 0. An emissivity of 1 means that the object is both a good radiator and absorber of IR radiation. An emissivity near 0 means the object is a good reflector of IR radiation but a poor IR emitter. For example (link Emissivity coefficients ) black body matt is 1.0 (very good emitter and absorber) and Aluminum sheet is .09 (near zero so a good IR reflector and poor emitter).

The propane heater has a shiny Aluminum cap that has an emissivity near zero so is a good reflector of IR energy. Good by design for reflecting IR heat from the burner down towards people sitting under the heater. The Aluminum cap also is a poor emitter so less IR is radiated upwards where the energy is just wasted. However, there is a lot of air flow convection heat energy carried upwards over the top heater cap.

The idea with the black corrugated metal shield placed above the propane heater is to capture as much of the air flow convection and upwards radiation from the Propane heater and then radiate as much of that heat back downwards towards the intended recipients. I.e., capture and re-radiate upwards heat from the propane heater that would have been lost. Since a lot of energy is radiated back downards by the metail shield, that energy also does not end up heating the ceiling.

The metal heat shield suspended above the heater needs to best capture and re-radiate IR energy. So the metal shield needs an emissivity as close to 1 as possible. This is why the corrugated metal shield is panted with a high temperature flat black paint. For an analysis below, we will assume the emissivity of the flat black painted metal shield is .9.

The other goal is to limit heat escaping upwards from the shield that would both reduce efficiency and heat the ceiling above the shield. This is accomplished with as much insulation as possible on the top side of the shield. The insulation has to withstand the temperature created by the shield capturing heat energy.

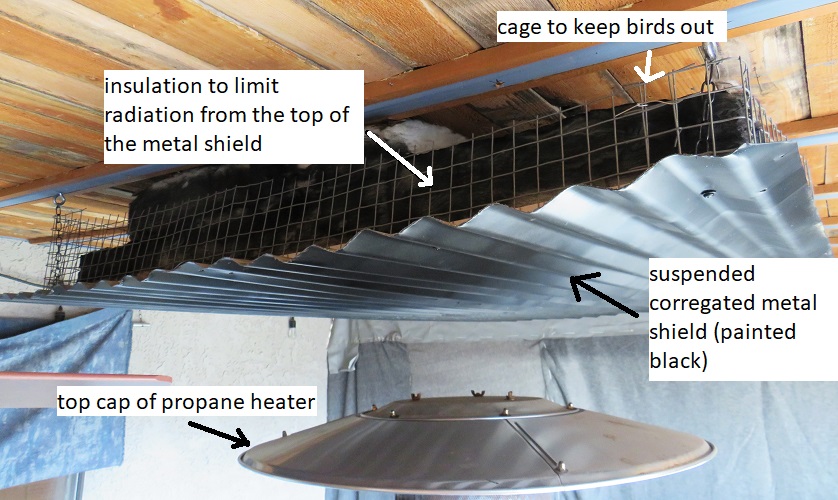

Picture below of the Propane heater and shield in action

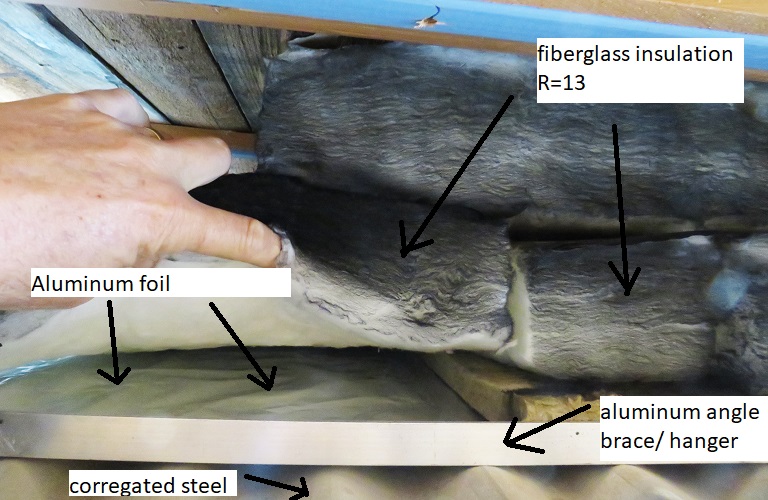

Construction

Aluminum angle on the two ends of the shield fasten the two six foot length corrugated steel roofing pieces together (screws/ nuts) and provide an attachment point for hanging the heat shield. The entire top of the corrugated steel assembly is covered by sheets of Aluminum foil. Aluminum foil is a very good IR reflector (emissivity is .04) and with the air spaces created by the corrugated steel is the first layer of insulation and melts at a very high temperature (660C). On top of this is just hardware store fiberglass batten insulation with the batt facing away from the heat shield. The melting temperature of fiberglass is typically in the range of 540C.

The goal here is to capture as much convection and radiated heat leaked off the top of the propane heater and then re-radiate that heat downwards. IR radiation goes up with temperature so the top metal shield will get hot. My IR thermal measurement tool only goes to 100C and the very middle of the shield does exceed this. But its only a fairly small area - maybe a circle of one foot diameter. Since I don't have the tool to actually measure how hot the shield gets I'm taking some risk. But based on gradients I have seen, I feel comfortable that the temperature stays under 200C and this is a fair margin below the Aluminum foil and fiberglass ratings. Some risk.. but I think its small. If I ever see a problem I will certainly note it here. Note the black color on the fiberglass insulatin is just spray paint (cosmetic only).

Measured results (radiated power downwards is 733 watts at the lowest Propane heater setting.

With the Propane heater on its lowest setting and allowing enough time for the shield to stabilize in temperature, the IR radiated power of the shield is calculated at 733 watts. The method for calculating radiated power uses the equation from here black body radiation. The finished heat shield dimension are 72 inch by 44 inch and twenty two evenly spaced readings were taking using a hand held IR thermometer. The temperature of the heat shield is not uniform so it was divided into three regions (center, mid and outer) and the temperature readings were averaged per region. The center region is the hottest and gets cooler as you move towards the outer edge. Temperatures are converted to Kelvin and plugged into the equation in the link. The emissivity for the black body metal heat shield was assumed to be .9. The power from each region was calcuted, then added together to arrive at the total radiated emission power of 733 watts. This is for the lowest Propane heater setting, the shield radiated power will go up as the Propane heater setting is increased.

Discussion... The shield captured and re-radiated 733 watts on the lowest heater setting that would have been lost to the sky. An intermediate experiment had been done with and without the top insulation and the insulation did significantly raise both the temperature of the shield and radiated IR emission. I.e., the insulation significantly improves the efficiency. The temperature of the ceiling outside of the shield was also kept to between 27 and 43C (81 to 110F - well below summer ambient temps in this area). The shield seems to be effective at both keeping the ceiling temperature at a safe lower level and also capturing and re-radiating a lot of heat the would have been lost. The shield got a fair amount of use this winter and you can feel the extra nicely dispersed radiant heat by the metal sheild especially in lighter wind conditions. If its windy, all the ambient air flow keeps the shield from heating up but also elimitates any risk of the ceiling heating up. The extra radiated power of the shield pretty much allowed us to use the Propane heater on the lowest setting making the tank last considerably longer.

For comparison, when in use, the shield described in this experiment puts out the power of between the 600W and 800W Wextar infrared electric wall heaters.

Extra stuff

Also. Picture below is of an experimental propane fire pit "black body" heat reflector. This spot has a view so everyone only sits on one side and heat on the view side just gets wasted.. I didn't do any measurements but it seems to help by getting hot and re-radiating towards where we sit. This reflector has one inch thick high temperature insulation on the back side of the metal shield to increase temperature and hence black body radiation.